Previously, I went through an explanation of how to develop this form. In this post, i will look at the process of slicing it up.

First things first, i laid out a series of reference lines along the length of loaf. I then went ahead programmed some parameters to control the spacing of these lines which are intended to locate the center between ribs.

These are the parameters involved:

Then I pick each line individually and hit the CREATE FORM button. It extrudes a nice 2D surface upwards.

This is where it gets interesting. Then i pick the edge lines of each surface, you may have to hit the TAB key once or twice to cycle through the options. Having selected the edges of the surface, i hit CREATE FORM again and a box is extruded.

I link the positive and negative offsets of the box to the VOID_Thickness Half parameters.

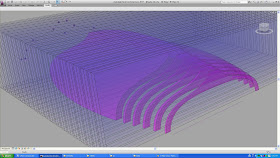

And the boxes all line out to exactly how i want:

And I can start slicing using the CUT command....

Oh how happy I am!

Until i try to flex the form, which was the point of the whole exercise anyways, and then:

AAARARRARAGGGGGHHH!!!!! I made the fatal error of using model lines to define the ends of my form. I go back and start from scratch, generating the profiles as REFERENCE LINES!!!! 9 out of 10 times, when forms don't do what i want, its because i used model lines rather than reference lines. I am a forgetful troublemaker sometimes....grrrr....

But NOW, I am kickin' it with a big smile.....

No comments:

Post a Comment